Cleanroom flooring is an important component of cleanroom facilities. It needs to meet specific cleanliness requirements to ensure that it does not cause pollution during its use. So, how to choose the flooring for a cleanroom, and which type of flooring material is most suitable for a cleanroom? HUIYA, a supplier with commercial flooring production experience, provides professional Clean Room Flooring solutions in this article.

What is a cleanroom? And why is the choice of flooring important to it?

A cleanroom is a controlled environment in which parameters such as dust, microbes, aerosol particles, chemical gases, temperature, humidity, and pressure are strictly controlled. These environments are mainly used for scientific research and industrial production, such as semiconductor and pharmaceutical manufacturing, where very low environmental pollution is required.

The choice of flooring for a cleanroom is important for reasons including:

- Pollution control: The floor can be a source of dust and microbes. If not properly cleaned and maintained, it can lead to pollution in the cleanroom. Therefore, a material that reduces the accumulation of particles and microbes and is easy to clean should be chosen.

- Durability and maintenance: Cleanroom flooring needs to be able to withstand heavy use, including foot traffic and equipment movement. Therefore, durable and easy-to-maintain flooring is needed.

- Safety of personnel and equipment: The floor needs to provide a non-slip surface to prevent slip and fall accidents. In cleanrooms for electronics and semiconductor manufacturing, the floor needs to have antistatic properties to prevent static build-up, which could affect sensitive electronic equipment or cause a fire.

- Regulations and standards: Many industries and countries have specific regulations and standards for cleanroom flooring. Flooring that meets these regulations and standards should be selected.

Therefore, choosing the right cleanroom flooring is essential. It can help ensure the cleanliness of the cleanroom, meet the safety needs of workers and equipment, and meet industry and national regulations and standards.

Cleanroom Flooring Requirements and Specifications

As mentioned above, we know that cleanroom flooring has an impact on production efficiency and safety. Therefore, the design and selection of cleanroom flooring need to consider many factors to ensure that it meets the special requirements of the cleanroom. Here are some key requirements:

- Durability: The floor needs to be able to withstand heavy use, including load weights, pedestrian traffic, and equipment movement.

- Smooth and seamless: The floor should be very smooth, without cracks or gaps, to prevent the accumulation of dust and microbes.

- Easy to clean and disinfect: Cleanroom floors need to be easy to clean and disinfect to remove dust, microbes, and other potential sources of contamination.

- Chemical resistance: The floor needs to be able to resist erosion from cleaners, disinfectants, and other chemicals that may be used in the cleanroom.

- Antistatic: In some applications, the floor may need to have antistatic properties to prevent static build-up, which could affect sensitive electronic equipment or cause a fire.

- Slip resistance: The floor needs to provide sufficient slip resistance to ensure the safety of workers and visitors.

- Environmental protection: Flooring materials should have good environmental performance and not pollute the environment.

- Compliance with regulations and standards: The floor needs to comply with relevant cleanroom regulations and standards, which may include ISO standards, U.S. Federal Standard 209E (now replaced by ISO standards), and other relevant industry or national standards.

These requirements need to be considered in conjunction with the specific type of cleanroom and application scenario. Different cleanrooms may have different flooring requirements, for example, in biomedical cleanrooms, the floor may need to have higher resistance to microbial erosion. Therefore, when choosing cleanroom flooring, the most suitable choice should be made based on specific application requirements.

Clean Room Flooring Options

Cleanrooms require special flooring solutions due to the unique demands of their environment. These floorings need to be smooth, durable, easy to clean, and often need to be conductive to control static. Here are some options to consider:

- Vinyl Flooring: Vinyl flooring is a popular choice for cleanrooms. It’s smooth, durable, and easy to clean. Vinyl is also resistant to a lot of different chemicals, which can be beneficial in a cleanroom environment. Some vinyl flooring options are also available with antistatic properties.

- Epoxy Flooring: Epoxy flooring involves applying a layer of epoxy resin over the existing floor. This creates a smooth, seamless surface that’s very easy to clean. Epoxy flooring is also quite durable and can withstand heavy traffic. There are ESD (Electrostatic Discharge) epoxy options specifically designed for environments that need to control static.

- Rubber Flooring: Rubber flooring is another option for cleanrooms. It’s highly durable and resistant to chemicals. Rubber is also a good choice for areas where people will be standing for long periods of time, as it’s more comfortable underfoot than some other options. Some rubber flooring options are also antistatic.

- Polyurethane Flooring: Polyurethane flooring is a high-performance solution for cleanrooms. It’s extremely durable, resistant to chemicals, and easy to clean. Polyurethane floors can be made to be antistatic, and they provide a seamless, non-porous surface that won’t harbor bacteria or other contaminants.

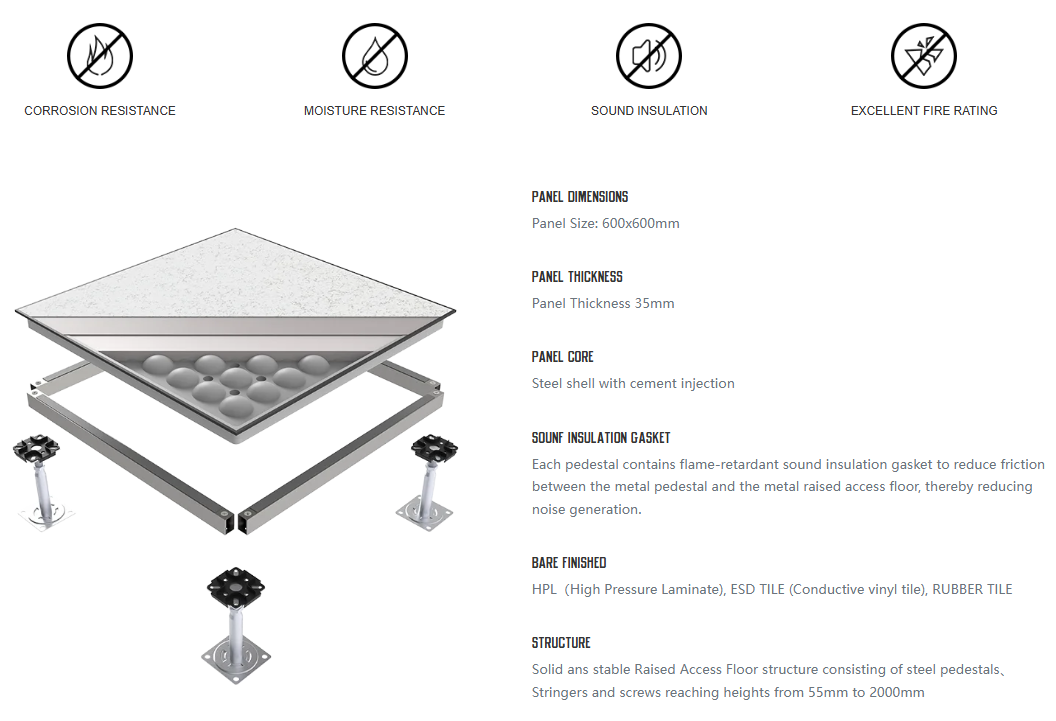

- Raised Access Flooring: In some cleanrooms, it’s beneficial to have raised access flooring. This allows for easy access to services and cabling under the floor. The panels in these floors can be made from a variety of materials, including those listed above.

- Acrylic Flooring: Acrylic flooring is another seamless option that’s easy to clean and resistant to chemicals. It’s also quite durable and can withstand heavy traffic. Some acrylic flooring options are also antistatic.

Here’s a comparison table for the cleanroom flooring options previously mentioned:

| Flooring Type | Durability | Ease of Cleaning | Chemical Resistance | ESD Options Available | Other Benefits |

| Vinyl | High | High | High | Yes | Cost-effective |

| Epoxy | High | High | High | Yes | Seamless and non-porous |

| Rubber | High | Moderate | High | Yes | Comfortable underfoot |

| Polyurethane | Very High | High | Very High | Yes | Extremely durable, seamless and non-porous |

| Raised Access | Varies | Varies | Varies | Varies | Provides access to services and cabling beneath |

| Acrylic | High | High | High | Yes | Durable, seamless and non-porous |

The “best” flooring for a cleanroom depends on a variety of factors, including the use of the cleanroom, the required level of sterilization, the chemicals used within the room, and the amount of foot traffic or heavy machinery use.

What is the Best Flooring for a Clean Room?

Here are a few top options, but remember that the best choice may differ depending on your specific requirements:

- Epoxy Flooring: Epoxy flooring is often a top choice for cleanrooms. It offers a seamless and non-porous surface that is easy to clean and disinfect. It’s also highly durable and resistant to many chemicals, making it suitable for heavy-duty use. ESD (Electrostatic Discharge) epoxy options are available for environments that need to control static.

- Vinyl Flooring: Vinyl flooring is another popular choice due to its durability and ease of cleaning. It’s also chemically-resistant and can be made antistatic. Vinyl is a more cost-effective option than some other flooring types.

- Polyurethane Flooring: For cleanrooms requiring a very high level of cleanliness, polyurethane flooring can be an excellent choice. It’s extremely durable and easy to clean, providing a seamless, non-porous surface. It’s also resistant to a wide range of chemicals and can be made antistatic.

- Raised Access Flooring: In cleanrooms that need frequent access to services and cabling under the floor, raised access flooring can be the best option. The panels in these floors can be made from a variety of materials, including those mentioned above.

The best way to determine the most suitable flooring for your cleanroom is to consult with a cleanroom design expert or a flooring specialist. They can take into account all the variables specific to your cleanroom and recommend the most appropriate flooring solution.

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS