The overhead support structure makes the access floor convenient for line management and air distribution in many places, but it also makes anyone concerned about these issues before choosing a raised floor: “Is the raised access floor stable enough for long-term support?” or “What is the maximum weight that the raised floor support?” Yes, the load and weight-bearing capacity of the raised floor are crucial and is also a key factor in testing the quality of the entire system.

So when designing or evaluating raised floor systems, especially in data centers, server rooms, or other technical spaces, it’s crucial to understand various load types and perform the appropriate calculations to ensure the integrity and safety of the floor system. Here, we’ll cover the basic concepts and calculations for different types of Static and Dynamic loads that raised floors need to withstand: concentrated load, ultimate load, uniform load, impact load, and rolling load.

Raised Floors Load & Weight Capacity (Types, Testing, Calculation, Rating)

The Raised Access Floor load capacity refers to the maximum weight the floor system can handle without failure. This includes the static weight of all equipment, furniture, and any dynamic loads (like human traffic). Load capacities are generally specified in pounds per square foot (psf). In this case, the testing of Raised Access Floor Load Capacity will be conducted in two forms: Static Loads and Dynamic Loads.

Raised Access Floor Static Loading (Testing, Calculation, and Rating)

The raised floor static load refers to the maximum weight or force per unit area that a raised floor system can support without causing permanent deformation or failure when the load is evenly distributed and stationary. In other words, it is the maximum uniformly distributed static (non-moving) load that the raised floor can safely bear without collapsing or sustaining damage.

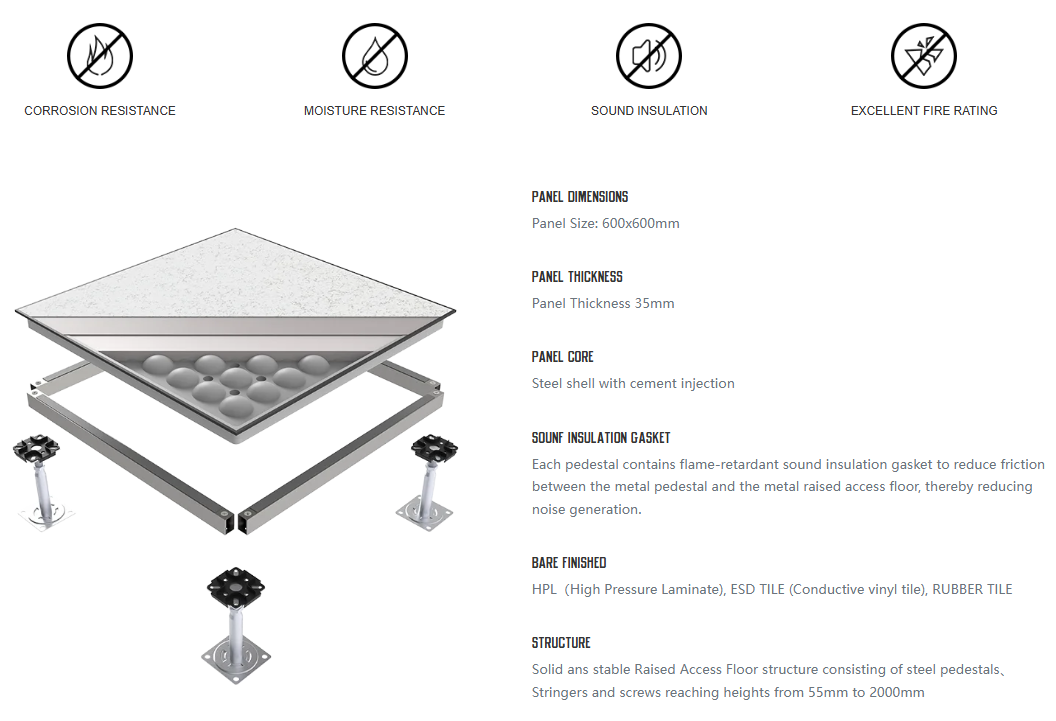

The raised floor static load is typically expressed in pounds per square foot (psf) or kilograms per square meter (kg/m²) and is determined by the design and materials used in the raised floor system, including:

- The strength of the floor panels

- Capacity of the pedestals and stringers (support structure)

- Spacing and layout of the pedestals and stringers

Raised Floor Static Load Types

When testing raised floor static load, three key terms are often used: Concentrated Load, Uniform Load, and Ultimate Load. Each of these terms describes a different aspect of the floor’s ability to bear weight and withstand stress.

1. Concentrated Load

The concentrated load is a localized load applied over a small area, such as the weight of a heavy equipment or a storage rack on a single floor panel or a group of panels. The concentrated load rating represents the maximum point load that the raised floor system can withstand without failure or excessive deflection.

Testing:

Purpose: To determine the maximum load that can be supported at a specific point on the floor without failure.

Procedure:

- Point Load Application: A load is applied at a single point on the floor panel, often using a hydraulic ram or a similar device.

- Incremental Increase: The load is increased incrementally until the specified maximum load is reached or until the panel shows signs of failure (e.g., deformation, cracking).

- Measurement and Observation: Measurements of deflection (how much the panel bends under load) and any permanent damage are recorded. The test assesses both the immediate impact and the residual effects once the load is removed.

Calculation:

Concentrated Load (P) is usually provided by the manufacturer’s specifications. It’s measured at the weakest point of the panel (often the center).

Formula:

Manufacturers typically test this according to standards such as CISCA (Ceilings and Interior Systems Construction Association) where a load is applied at the center of the panel and the deflection is measured. The load at which the panel fails or deforms unacceptably is the maximum concentrated load.

2. Uniform Load

The uniform load is a load that is evenly distributed over the entire raised floor area. The uniform load rating, also known as the static load rating or design load, represents the maximum weight per unit area that the raised floor system can support when the load is spread out uniformly across the entire surface.

Testing:

Purpose: To verify that the floor can sustain a specified load evenly distributed over its entire surface.

Procedure:

- Even Distribution: A large area or the entire floor is loaded uniformly. This can be simulated using uniformly distributed weights or a specially designed load frame that applies pressure across the entire panel surface.

- Monitoring: The load is typically applied in steps, and each step is maintained for a specific period. Observations for any deformations or structural weaknesses are made.

- Assessment: Check for any permanent deformation or failure after the load is removed, ensuring the floor returns to its original condition without damage.

Calculation:

Ultimate Load Capacity is typically calculated by applying a factor of safety to the concentrated load.

Formula:

- Ultimate Load = Concentrated Load ×Factor of Safety

- Ultimate Load=Concentrated Load×Factor of Safety

- Factor of Safety: Commonly ranges from 2 to 3, depending on the application and local regulations.

3. Ultimate Load

The ultimate load is the maximum load that a raised floor system can withstand before catastrophic failure occurs. It is typically calculated by applying a safety factor to the design load or uniform load rating. The ultimate load rating is used to ensure that the raised floor system has an adequate margin of safety to withstand unexpected or temporary overloads.

Testing:

Purpose: To determine the maximum load the flooring system can withstand before structural failure occurs. This test is critical for establishing safety margins.

Procedure:

- Extreme Load Application: Load is applied in a controlled environment to exceed the normal operational loads significantly. Often, this load is up to two or three times the normal maximum expected load.

- Observation of Failure Modes: The point of failure is identified, noting how and when the floor fails, which provides data on the safety factors incorporated into the floor design.

- Safety Assessment: This test helps in assessing the ultimate safety and risk factors associated with the floor system under extreme conditions.

Calculation:

Uniform Load (q) is expressed in pounds per square foot (psf).

Formula:

The total weight supported by the floor system is divided by the total area of the floor.

q= Total Area / Total WeightRaised Floor Static Loading Rating Chart

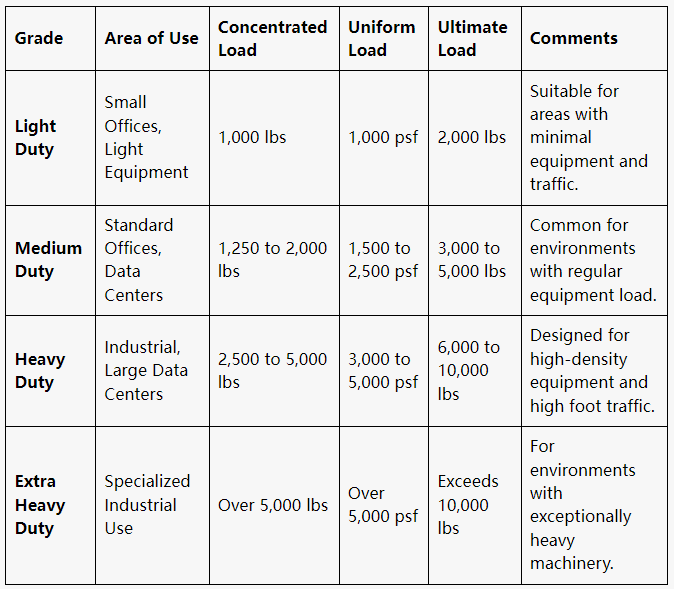

Below is a table that summarizes the static load ratings for raised floors, including Concentrated Load, Uniform Load, and Ultimate Load, along with typical areas of use and the grading of the floor in terms of load-bearing capacity. This table can help in selecting the appropriate raised floor system based on the specific needs and load requirements of different environments.

Raised Access Floor Dynamic Load (Testing, Calculation, Rating)

Dynamic loads on raised floor systems are caused by moving or changing loads, such as rolling equipment, vibrations, or impacts. These loads are typically more severe than static loads and require higher load ratings to ensure the structural integrity and safety of the raised floor system.

Dynamic loads are typically more severe than static loads and can cause greater stress and fatigue on the raised floor components. As a result, raised floor systems are designed with higher load ratings for dynamic loads compared to static loads to account for these additional forces.

The dynamic load ratings for raised floor systems are usually expressed as a multiple of the static load rating, such as 2 times or 3 times the static load rating. For example, if a raised floor system has a static load rating of 1,500 lbs/sq.ft, its dynamic load rating might be 3,000 lbs/sq.ft or higher.

Raised Floor Dynamic Load Types

There are several types of dynamic loads that need to be considered for raised floor installations:

1. Rolling Load

Rolling loads are caused by equipment or objects being rolled or moved across the raised floor surface, such as server racks, carts, or pallet jacks. The concentrated weight combined with the rolling motion creates a dynamic load that can be significantly higher than a static load.

Testing:

Purpose: To determine the maximum rolling load that the raised floor system can withstand without failure or excessive deflection.

Procedure:

- Load Application: A heavy load, such as a server rack or equipment, is placed on a wheeled cart or dolly.

- Rolling Movement: The wheeled load is rolled across the raised floor surface in various directions and patterns, simulating the movement of equipment during installation or maintenance.

- Measurement: Deflection of the floor panels and any signs of stress or damage to the floor components are carefully monitored and recorded.

- Load Increment: The weight of the rolling load is gradually increased, and the rolling movement is repeated until the maximum safe load or the failure point is reached.

Calculation:

The rolling load capacity is typically expressed as a multiple of the static load rating, considering the additional forces and stresses caused by the rolling motion.

Formula: Rolling Load Capacity = Safety Factor × Static Load Rating

Where:

Safety Factor is a multiplier that accounts for the dynamic nature of rolling loads, typically ranging from 2 to 3 or higher, depending on the application and manufacturer guidelines.

Static Load Rating is the maximum uniformly distributed load that the raised floor system can support without failure or excessive deflection.

Example:

If a raised floor system has a static load rating of 1,500 lbs/sq.ft and a safety factor of 2.5 is applied for rolling loads, the rolling load capacity would be:

Rolling Load Capacity = 2.5 × 1,500 lbs/sq.ft = 3,750 lbs/sq.ft

This means that the raised floor system should be able to withstand rolling loads up to 3,750 lbs/sq.ft without failure or excessive deflection, provided that the load is properly distributed and the rolling movement is within the design parameters.

2. Vibration Load

Vibration loads on raised floor systems are caused by equipment or machinery installed on the raised floor that generates vibrations. These vibrations can create dynamic loads on the floor panels and support structure, potentially causing fatigue and failure over time if not accounted for in the design.

Testing:

Purpose: To determine the maximum vibration load that the raised floor system can withstand without excessive deflection, resonance, or failure.

Procedure:

- Vibration Simulation: A vibration testing machine or shaker table is used to apply controlled vibrations to the raised floor system. The vibrations can be adjusted in frequency, amplitude, and duration to simulate various operating conditions.

- Instrumentation: Sensors, such as accelerometers, strain gauges, and deflection meters, are attached to the raised floor components to measure the vibration response and stresses.

- Vibration Sweep: The vibration testing machine applies a range of frequencies and amplitudes to the raised floor system, starting from low levels and gradually increasing until the maximum safe vibration load or the failure point is reached.

- Data Collection: The vibration response data, including accelerations, deflections, and strains, are recorded and analyzed to identify any resonance frequencies, excessive deflections, or potential failure modes.

Calculation:

The vibration load capacity is typically expressed as a maximum acceptable acceleration level or a force amplitude, depending on the specific vibration characteristics and the raised floor system design.

Formula:

Vibration Load Capacity = Safety Factor × Maximum Acceptable Vibration Level

Where:

Safety Factor is a multiplier that accounts for uncertainties and potential variations in the vibration loads, typically ranging from 1.5 to 2 or higher, depending on the application and manufacturer guidelines.

Maximum Acceptable Vibration Level is the maximum vibration amplitude or acceleration that the raised floor system can withstand without excessive deflection or failure, as determined by the vibration testing and analysis.

Example:

If the vibration testing and analysis determine that the maximum acceptable vibration level for a raised floor system is 0.5 g (g = acceleration due to gravity), and a safety factor of 1.8 is applied, the vibration load capacity would be:

Vibration Load Capacity = 1.8 × 0.5 g = 0.9 g

This means that the raised floor system should be able to withstand vibration loads up to 0.9 g without excessive deflection or failure, provided that the vibration characteristics are within the design parameters.

3. Impact Load

Sudden impacts or drops of heavy objects onto the raised floor surface can generate short-duration, high-intensity dynamic loads. These loads can be caused by accidental drops, seismic events, or other unexpected occurrences.

Testing:

Purpose: To determine the maximum impact load that the raised floor system can withstand without excessive deflection, damage, or failure.

Procedure:

- Impact Test Setup: A controlled impact testing apparatus, such as a drop weight or pendulum impact device, is used to apply impact loads to the raised floor system.

- Instrumentation: Sensors, such as accelerometers, load cells, and deflection meters, are attached to the raised floor components to measure the impact response and stresses.

- Impact Load Application: A known weight or mass is dropped or impacted onto the raised floor surface from a specific height or angle, simulating various impact scenarios.

- Data Collection: The impact response data, including impact forces, accelerations, deflections, and strains, are recorded and analyzed to identify any potential failure modes or excessive deflections.

- Load Increment: The impact weight or height is gradually increased, and the impact test is repeated until the maximum safe impact load or the failure point is reached.

Calculation:

The impact load capacity is typically expressed as a maximum impact force or energy level that the raised floor system can withstand without failure or excessive deflection.

Formula: Impact Load Capacity = Safety Factor × Maximum Acceptable Impact Force

Where:

Safety Factor is a multiplier that accounts for uncertainties and potential variations in the impact loads, typically ranging from 1.5 to 2 or higher, depending on the application and manufacturer guidelines.

Maximum Acceptable Impact Force is the maximum impact force or energy level that the raised floor system can withstand without excessive deflection or failure, as determined by the impact testing and analysis.

Example:

If the impact testing and analysis determine that the maximum acceptable impact force for a raised floor system is 5,000 lbf (pound-force), and a safety factor of 1.8 is applied, the impact load capacity would be:

Impact Load Capacity = 1.8 x 5,000 lbf = 9,000 lbf

This means that the raised floor system should be able to withstand impact loads up to 9,000 lbf without excessive deflection or failure, provided that the impact characteristics are within the design parameters.

4. Seismic Load

In areas prone to earthquakes, the raised floor system must be designed to withstand dynamic loads caused by seismic activity. Seismic loads can create horizontal and vertical forces that can potentially damage or displace the raised floor components.

Testing:

Purpose: To determine the seismic load capacity of the raised floor system and its ability to withstand earthquake-induced forces without excessive deflection, damage, or failure.

Procedure:

- Shake Table Testing: A large-scale shake table is used to simulate earthquake ground motions and subject the raised floor system to realistic seismic loads.

- Instrumentation: Accelerometers, displacement sensors, and strain gauges are installed on the raised floor components to measure the response to the simulated seismic loads.

- Seismic Input: The shake table is programmed to apply specific earthquake ground motion records or design-level seismic inputs based on the expected seismic hazard at the installation location.

- Response Monitoring: The response of the raised floor system, including accelerations, displacements, and strains, is continuously monitored and recorded during the simulated seismic event.

- Damage Assessment: After the seismic testing, the raised floor system is inspected for any signs of damage, such as cracking, permanent deformation, or component failure.

Calculation:

The seismic load capacity of a raised floor system is typically expressed in terms of the maximum expected ground acceleration or seismic design force that the system can withstand.

Formula: Seismic Load Capacity = Safety Factor × Design Seismic Force

Where:

Safety Factor is a multiplier that accounts for uncertainties and potential variations in the seismic loads, typically ranging from 1.5 to 2 or higher, depending on the seismic design code and manufacturer guidelines.

Design Seismic Force is the maximum expected seismic force or ground acceleration that the raised floor system needs to resist, as determined by the seismic hazard analysis and design codes for the specific installation location.

Example:

If the seismic hazard analysis and design codes indicate that the raised floor system should be designed for a maximum ground acceleration of 0.4 g (g = acceleration due to gravity), and a safety factor of 1.8 is applied, the seismic load capacity would be:

Seismic Load Capacity = 1.8 × 0.4 g = 0.72 g

This means that the raised floor system should be able to withstand seismic loads up to 0.72 g without excessive deflection, damage, or failure, provided that the seismic design and installation are in accordance with the applicable building codes and standards.

Raised Floor Static Loading Rating Chart

Below is a structured table that provides an overview of different types of dynamic loads that a raised floor system may encounter, including Rolling Load, Vibration Load, Impact Load, and Seismic Load. The table also details typical areas of use for each grade of raised flooring and categorizes the floors by their ability to withstand various intensities of dynamic loads.

| Grade | Area of Use | Rolling Load | Vibration Load | Impact Load | Seismic Load | Comments |

| Standard | Office Spaces, Light Data Centers | Moderate | Low | Moderate | Low | Suitable for environments with light equipment and occasional rolling loads. |

| Enhanced | Data Centers, Server Rooms | High | Moderate | High | Moderate | Designed for areas with frequent equipment movement and moderate seismic activity. |

| Heavy Duty | Industrial, Large Data Centers | Very High | High | Very High | High | Capable of supporting heavy equipment, significant impact, and higher vibration levels. |

| Seismic-Grade | Areas Prone to Earthquakes | High | High | High | Very High | Specifically engineered to withstand seismic events, ideal for geologically active are |

That’s all you need to know about the Raised Floor Load. If you are considering finding the most solid floor support system for your project, contact HUIYA experts now, they will give you the most satisfactory solution!

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS