5S, TPS, and JIT Intelligent Raised Access Floor Manufacturing at HUIYA Factory

Nowdays, where high-quality, intelligent buildings continuously drive urban upgrades, raised floors are not only a key foundation for flexible space partitioning and system wiring, but also an important carrier for the implementation of new scenarios such as green energy saving, healthy offices, and smart living. As a synonym for innovation and reliability in the industry, Huiya has always stood at the forefront of industry development, empowering every niche application scenario with leading product capabilities, a comprehensive management system, and rich project experience. Here we will systematically review Huiya’s professional layout in various raised floor fields, showcase its high-standard solutions through real-world cases, and deeply analyze Huiya’s lean factory management practices, revealing how it continues to lead the industry’s high-quality and sustainable development.

Deep Focus and Dedicated Service: HuiYa Professional Raised Floor Series

In-depth Segmentation and Innovative Layout in the Raised Access Floor Field

As one of China’s most influential providers of overall raised access floor solutions, Huiya has always focused on the development of raised floors, systematically segmenting its product and service structure to meet rapidly changing market demands, and refining its operations. Guided by the approach “smart space, green production, and global standards,” Huiya works steadily on three major sectors: indoor raised floor systems, outdoor raised floor systems, and Japanese-inspired double-platform floor systems.

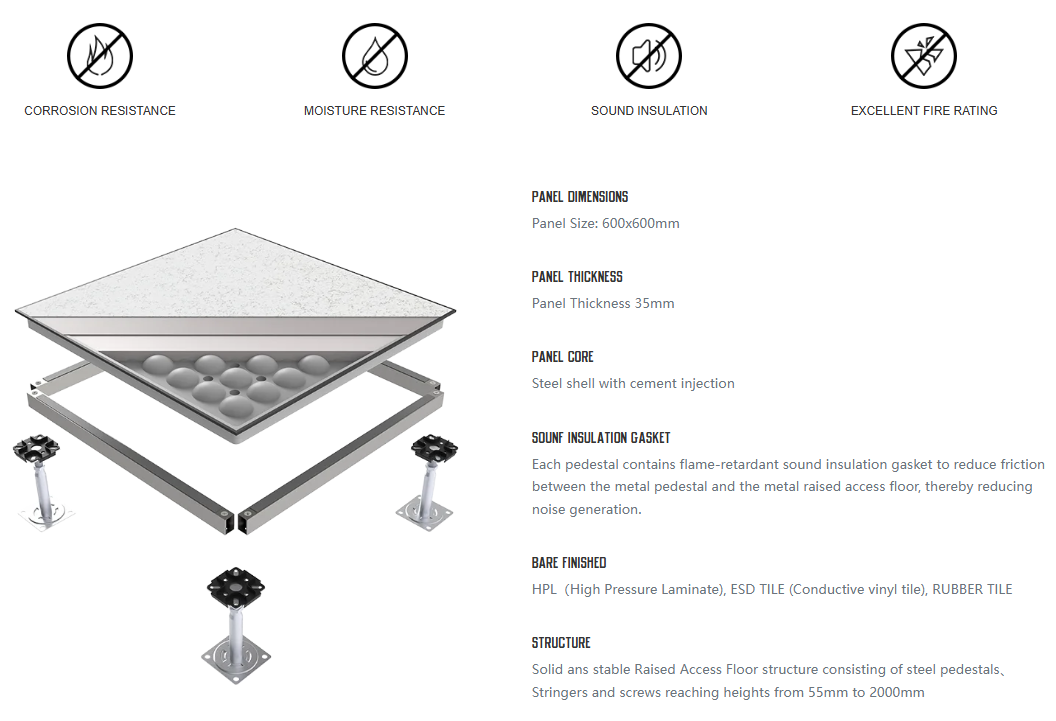

1. Indoor Raised Access Floor Segment

Huiya is based on indoor space scenarios such as big data, intelligent offices, and green buildings, offering multiple categories of flooring systems including steel cement boards, calcium sulfate boards, particleboard, steel-clad boards, all-steel anti-static boards, and ventilated boards. Each product strictly adheres to the highest domestic and international standards, including Chinese GB, European and American EN, American CISCA, and Japanese JIS, achieving a unified balance of load-bearing strength, fire resistance, wear resistance, anti-static properties, flexible wiring, and convenient modification, making it the preferred choice for data centers, financial computer rooms, new office buildings, and smart education spaces.

Application Scenarios and Product Advantages:

Specifically designed for modern intelligent spaces such as office buildings, data centers, commercial complexes, and public buildings, the product system covers steel cement boards, high-density calcium sulfate boards, and anti-static particleboard.

Typical Cases:

Shanghai Hongqiao Jingyao Plaza (115.000㎡): Utilizes SC steel-cement raised flooring to meet the complex wiring, high load-bearing capacity, high-standard anti-static requirements, and flexible space adjustment needs of a large-scale office cluster.

Shanghai Xinjiangwan City Douyin Building (106.707㎡): Achieves an integrated and efficient space for big data centers and internet offices. The SC series raised flooring fully leverages its high load-bearing capacity and environmentally friendly advantages to ensure the safe and stable operation of data equipment.

2. Outdoor Raised Access Floor Segment

For special application scenarios such as rooftop gardens, open-air platforms, and outdoor landscapes, Huiya has developed corrosion-resistant, lightweight, and flexible raised flooring systems (such as GRC cement fiberboard, aluminum alloy panels, and ceramic panels) to solve the technical challenges of traditional structures in areas such as anti-slip and anti-freeze properties, UV aging resistance, drainage, and root penetration prevention. Huiya has also collaborated extensively with several internationally renowned landscape design companies and landscape engineering contractors.

Huiya outdoor raised flooring products emphasize modular design and efficient installation, improving the overall construction efficiency and ease of maintenance for landscape projects, and contributing to the construction of green ecological spaces in cities.

Application Scenarios and Product Advantages:

Targeting rooftop gardens, outdoor landscapes, and city terraces, this product emphasizes anti-aging, corrosion resistance, optimized drainage systems, and comfort compatibility. GRC (Glass Reinforced Concrete) cement fiberboard or ceramic raised platform systems are commonly used.

Typical Case:

Guangzhou Junchao Center (88.057㎡): Primarily used on the building’s multi-functional outdoor platform. Huiya’s GRC board solution ensures smooth drainage, excellent weather resistance and load-bearing capacity, effectively supporting both environmental beautification and space utilization needs.

3. Japanese-Style Double-Floor System Segment

HUIYA has introduced and localized Japan’s innovative double-floor raised system, advancing spatial upgrades in high-end residences, boutique apartments, and hotels. This system maximizes underfloor space utilization through an elevated design, enhances sound insulation and adaptive flexibility, and meets different user needs with improved comfort, safety, and responsiveness.

Application Scenarios and Product Advantages:

Focusing on diverse and flexible spaces in residences, apartments, and hotels, the modular elevated structure solves the problems of sound insulation, space reuse, and inconvenient floor wiring in traditional home furnishings, improving living comfort and space efficiency.

Typical Cases:

International Apartment Project Cooperation (Specific projects are confidential): For high-end residences/hotels, the localized innovative application of Japanese double-bed technology is introduced, achieving concealed wiring at the bottom, rapid modular transformation, and sound insulation layer enhancement, effectively improving the living experience and receiving extremely high praise from homeowners.

With an international R&D team and deep understanding of Japanese construction philosophy, HUIYA has developed high-performing double-floor systems with structure optimization, fire resistance, sound insulation, and flexible installation, catering to the refined demands of both Chinese and global customers.

Strategic Decisions: Supply Chain Integration Drives High-End Manufacturing

Huiya relies on China’s complete and globally leading manufacturing supply chain advantages, connecting upstream and downstream – raw materials, components, logistics, and services – through a data platform to achieve efficient collaboration across the entire chain.

Our firm looks beyond basic production, integrating resources and managing key stages:

We collaborate with raw material suppliers to optimize the procurement structure, achieving continuous traceability and green, low-carbon practices for raw materials;

With our own factory at the core, it independently produces core components (steel, GRC, ceramics, etc.), controlling key processes;

We have established deep partnerships with major logistics service providers nationwide to ensure timely and accurate delivery of large-scale projects.

Huiya keenly observes that high-quality supply chain integration is not only a competition of cost, but also a competition of quality and innovation. By streamlining the industrial chain, the company can flexibly respond to the market’s dual demands for customized and mass-produced manufacturing.

Lean Factory Management: Integrating 5S, TPS, and JIT for Intelligent Raised Flooring Manufacturing

In the raised floor manufacturing industry, high efficiency and consistent quality are fundamental to successful project progress. Huiya understands the impact of factory management on product performance, delivery time, and customer satisfaction, and actively adopts advanced manufacturing concepts, integrating 5S management, TPS, and JIT methods into actual production processes. Through the implementation of these systems, Huiya continuously improves its factory organization and resource allocation capabilities, ensuring the smooth and orderly operation of every process and providing customers with reliable raised floor solutions.

1. 5S Management – Practical Steps for Efficient Raised Floor Manufacturing

Originating from Japan, the 5S Lean manaufacturing is deeply implemented by Huiya in multiple dimensions, including factory production, warehousing, logistics, and quality assurance:

- – Sort (Seiri): Every type of steel, cement, and accessory is assessed by demand. Extra panels, unused hardware, and obsolete molds are promptly cleared, freeing up key workspaces for cutting, pressing, or assembly. This action prevents build-up around presses and in storage, removing trip hazards and supporting a steady workflow.

- – Set in Order (Seiton): Tools such as welding torches, drilling equipment, and measuring systems are assigned designated racks, labeled by color and use-frequency. Powder coating supplies, bolts, and finished panel stacks each have fixed bays in the facility. This setup allows assembly workers to pick up items without wasting time searching, keeping transfer lines running smoothly.

- – Shine (Seiso): Daily cleaning tasks are split by zone, with equipment operators responsible for checking machines for dirt or metal scrap, particularly around cutting tables and packing stations. Quick action on dust, spills, or misplaced components ensures that the assembly floor remains safe and the cutting area stays free of risks to product uniformity.

- – Standardize (Seiketsu): The organizing and cleaning methods are locked in with station checklists. Each workspace — from heavy steel forming presses to storage for GRC boards, follows set rules for upkeep and layout. Supervisors perform spot checks, and responsibility areas are marked on shop floor maps for easy tracking.

- – Sustain (Shitsuke): Ongoing staff participation in these routines builds a team habit of maintaining order by default. Operators of stamping lines, packaging teams, and QA units naturally look for improvement, helping to prevent errors and keep working conditions well-managed.

Through the 5S system, Huiya’s factory environment is clean and orderly, with extremely low safety risks. Employees’ sense of belonging, responsibility, and creativity are continuously improving, comprehensively enhancing the company’s soft power.

2. TPS (Toyota Production System) – Lean Flow in Raised Floor Manufacturing

Huiya applies the core TPS philosophy of “customer-centricity and eliminating all waste” to the raised floor manufacturing industry:

- – Kanban Pull System: Signs track progress of steel cutting, panel assembly, and powder coating in real time. The system signals exactly when to move prepped panels forward or initiate the next order, so storage at each station remains controlled and buffer zones are kept to a minimum.

- – Process Value Mapping: Staff members review the journey of GRC boards and steel frames from intake through to dispatch, identifying wait times in pressing, bottlenecks in curing ovens, or overstock of ceramic tiles. For example, on landmark jobs, panel drilling and finish-coating are analyzed for speed and smooth handover, reducing parts pile-up.

- – Flexible Production Lines: Raised floor orders often call for mixing several typologies or special under-floor accessories. Huiya’s production setup is arranged for fast changeover, so the same line can shift from high-strength panels to vented ones within a short span, matching project demands without halts.

- – Kaizen Teams: Workers on handling stations, welding booths, and packing lines collect and share their ideas for saving time or avoiding excess moves, helping management to update job methods or re-balance work across the factory.

- – Quick Changeover & Standardized Equipment: All production machines are set up for rapid tool swaps and shared fixture dimensions, so time spent moving from fiber cement to steel is minimized, and workers can respond quickly to priority shifts.

The in-depth implementation of TPS has helped Huiya build a “zero-waste, high-efficiency, and high-quality” production system, ensuring that every batch of raised flooring is delivered to customers with the highest cost-effectiveness and reliability.

3. JIT (Just-In-Time) – Fast Delivery, Less Waiting in Raised Floor Production

Huiya builds a flexible supply chain under the JIT model, continuously optimizing production and sales plans and scheduling:

- – Demand-Based Scheduling: Each production area, whether for steel frame assembly or GRC board laying, schedules work exactly against orders received. Quantities are calculated so teams collect only what’s due for the day or week, stopping excess.

- – Digital Tracking: All steps from procurement, cutting, assembly, coating, and shipping are traced in real time using integrated software platforms. This line of sight reduces the chance of missing parts or late dispatch in busy project phases.

- – Inventory Control: Raw material levels for plywood, adhesives, and hardware are reviewed daily. With lower stacks of parts on hand and only select reserves in staging, Huiya turns over warehouse stock quicker and limits unused inventory.

- – Fast Response on Major Jobs: On contracts needing large numbers of panels or special accessories, the planning system splits each job into stages, ordering sub-components, and organizing timely deliveries to the line. Finished goods are moved straight to shipping bays as soon as they clear final checks, keeping promised dates.

- – ERP+APS Scheduling: Smart production planning converts every project order into a customized run sheet, from raw material sourcing to QA inspection. Workplace layout and station staffing shift automatically to match workload, keeping all sections moving and supporting quick order turnarounds.

Employing an ERP+APS intelligent scheduling system, material requirements and production plans are generated in real time based on customer orders. For ultra-large orders such as the Guangzhou Junchao Center, the system automatically decomposes tasks and dynamically adjusts material procurement, ensuring that each batch of flooring/accessories arrives “as needed,” and finished products are immediately packed and shipped upon completion of the process, achieving zero redundancy and timely delivery. Through JIT (Just-In-Time) practices, Huiya has not only achieved efficient integration of production and market, but has also established “on-time delivery and zero delays” as a corporate benchmark.

Responsibility & Sustainable Development: Green Production Meets International Standards

Huiya highly values green environmental protection and corporate social responsibility. All its raised floor products have passed multiple authoritative standard certifications from China, the United States, the European Union, Japan, and South Korea, and have obtained the EPD (Environmental Product Declaration).

- Huiya insists on sourcing renewable and traceable raw materials to achieve green environmental protection in the raw material process;

- We have fully implemented solar photovoltaic power generation to reduce carbon emissions and energy consumption in its factories;

- Also, we have formulated clear life cycle management policies, actively participates in the formulation of industry green standards, and promotes low-carbon construction and green building development.

As one of the most innovative and influential manufacturers in China’s raised floor industry, Huiya will continue to build upon internationally advanced management systems such as 5S, TPS, and JIT, strengthen its supply chain integration capabilities, and promote the deep integration of diversified products with international standards to continuously create high-value-added overall raised floor solutions for global customers.

In the future, Huiya is willing to work with industry partners to promote a green, intelligent, and innovative new ecosystem of architectural spaces, allowing more people to enjoy a sustainable and high-quality spatial experience!

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS