In early cleanroom systems designed for electronic manufacturing, especially in flat panel display production, high levels of cleanliness are required. These facilities often employed vertical air ventilation systems. Traditionally, the flooring structure was constructed using a raised access floor system. These floors use adjustable pedestals, stringers, and floor panels, and, in cases with greater load requirements, steel beams are placed beneath the floor for extra support and leveling. All components must meet design standards and relevant national codes.

Raised floors are assembled with panels suspended above ground, creating a plenum for cable routing or airflow. Recently, the introduction of the “waffle slab” design offers a new approach for single-direction, vertical airflow in cleanrooms. The waffle slab features a vented, breathable surface, supports heavy equipment, and presents cavities on the cover plate to facilitate air circulation.

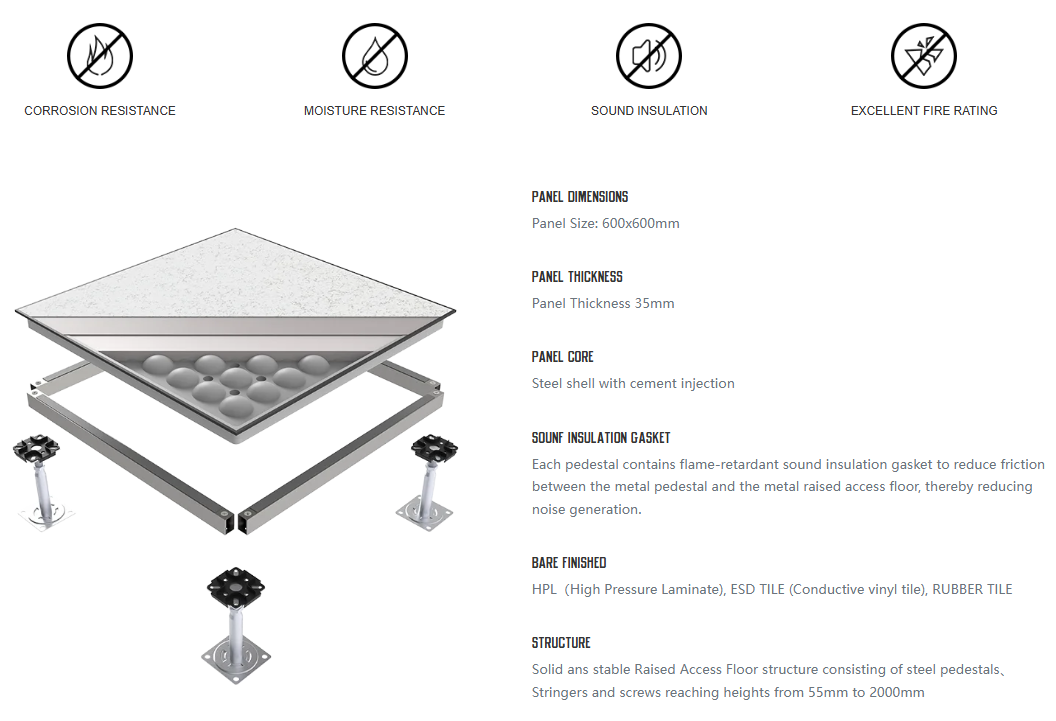

Raised Access Floor

Raised access floors, also termed anti-static floors, disperse charge safely when grounded or connected to a low potential. Improper handling can damage sensitive electronics. Static can occasionally trigger device issues or, at high energy levels, cause sparking upon discharge.

Typical panels measure 60 cm × 60 cm with a thickness of 55–60 mm, subject to variation by manufacturer and load requirement. The core is molded aluminum alloy, surfaced with anti-static PVC (2–3 mm) or stainless steel veneer (1–2 mm). Panel types include solid panels, perforated (honeycomb) panels (17–25% open area), grid panels (50% open area), and view panels—these allow monitoring and operation of equipment valves below the floor. These floors support loads exceeding 80 kg.

Installation

Installation involves placing pedestals, stringers, corner connectors, panel systems, testing, and quality control. Onsite temperature must remain between 5–35°C, and humidity below 80%. Pre-installation planning is critical to prevent misalignment and delays. Panels are cut as needed for optimal fit, and dust-free materials are used to seal boundaries.

The horizontal surface must be level and structurally sound, with non-slip, moisture- and flame-resistant properties. Metal parts receive rustproof finishes. All mechanical, anti-static, and appearance characteristics should meet SJ-10796 anti-static floor standards. Tools required include cutters, leveling devices, measuring tape, floor cleaning/polishing machines, testing electrodes, and meters.

Advantages

- Load Bearing:

Strong load capacity allows safe movement of staff, transport vehicles, and supports heavy production equipment, ensuring safety for both personnel and devices. - Ventilation:

Ceiling-mounted FFU units force air downward through perforated panels to generate laminar flow, aiding air replacement and humidity control. This design prevents corrosion and maintains breathable air for workers. - Static Dissipation:

These floors disperse static charge, preventing electrical discharge that could affect precision equipment or product performance. Compliance with Chinese standard SJ/T10796-2001 is required (surface or volume resistance of 2.5×104Ω2.5 \times 10^4 \Omega2.5×104Ω to 1.0×109Ω1.0 \times 10^9 \Omega1.0×109Ω).

Drawbacks

- Damage Risk:

The panel’s edges and central zones may be weak, risking structural damage under load or impact, especially if design or support is insufficient. This can be mitigated by reinforcing with additional support beams. - Vulnerability at Panel Centers:

Equipment moved across the floor may cause dents or pits, particularly if support legs concentrate loads in panel centers.

Waffle Slab Floor

The waffle slab floor is a newer structure for cleanrooms, consisting chiefly of panels with multiple perforations, mounting rings, and cover plates. Its design includes anti-static properties similar to raised access floors, but with improved installation results.

Installation

- Material and Tool Preparation:

Collect repair rings, quartz sand, talcum powder, epoxy resin, mixers, and cabinets. - Material Blending:

Mix epoxy resin, quartz sand, and talcum powder in correct ratios to create epoxy mortar. Use within specified times to avoid premature hardening. - Application:

Apply a uniform layer of epoxy using a scraper. Ensure complete coverage with no leakage. - Positioning:

Press repair rings into position with a scraper. - Setting and Leveling:

Adjust the surface height with a rubber mallet as necessary, monitored by laser leveling tools.

Benefits

- Simplified Process:

Installation is more straightforward compared to raised access floors. - Cost Efficiency:

The average price per square meter for a raised access floor is around 2,500 RMB. Waffle slab systems typically cost about 1,400 RMB per square meter, representing considerable savings.

Limitations

- Complexity:

Requires skilled labor and careful management of multiple installation steps. - Maintenance:

Periods of curing and protection are necessary. The floor should not bear loads or impacts during this time. - High Cleanliness Requirements:

The environment must be kept very clean. Epoxy mortar residue must be carefully managed to prevent difficult cleaning and future operational problems.

Raised Access Floor vs Waffle Slab Floor: What Are the Differences?

A direct comparison helps clarify the most relevant differences between raised access floors and waffle slab floors for cleanroom projects. The table below outlines their respective features:

| Feature | Raised Access Floor | Waffle Slab Floor |

|---|---|---|

| Structure | Elevated panels on adjustable pedestals, creating an accessible underfloor plenum | Integrated panels with multiple perforations, typically laid directly on the subfloor |

| Load Capacity | High; supports people, equipment, and AGVs | Good; appropriate for typical cleanroom weights, but may require assessment for very heavy loads |

| Static Control | Excellent; designed for anti-static performance in compliance with standards | Excellent; surfaces have anti-static properties |

| Ventilation | Very good; allows for laminar airflow through perforated/deck panels | Very good; multiple vent holes provide breathable flooring |

| Cable Management | Easy access for routing cables, pipes, and utilities in the underfloor space | Limited; typically not designed for cable routing |

| Installation | More complex, involves substructure assembly and leveling | Simpler process, less time-consuming compared to raised flooring |

| Cost | Higher material and installation costs (avg. ~2,500 RMB/sq.m) | Lower cost; approx. 1,400 RMB/sq.m |

| Maintenance | Panels can be lifted for inspection, maintenance, and cleaning | Requires regular upkeep; difficult to clean hardened epoxy residues |

| Construction Cleanliness | Moderate requirements; debris can be managed below the panels | High requirements; surfaces and materials must be kept free of contamination throughout installation |

| Customization | Multiple panel types (solid, perforated, grating, view), adaptable to project needs | Fewer variations, but suitable for most cleanroom air handling designs |

Raised Access Floor vs Waffle Slab Floor: Which One To Choose For Your Clean Room Project?

Selecting a flooring type depends on the specific functional needs, technical constraints, and budgetary parameters of your cleanroom project. Consider these criteria:

Choose Raised Access Floor When:

- You require substantial underfloor space for routing cables, chilled water pipes, or air return pathways.

- Heavy machinery, racks, or automated vehicles will regularly move or operate above the floor.

- The project prioritizes frequent, flexible maintenance and easy access to utilities.

- Compliance with strict anti-static or electrostatic discharge control is necessary, especially in advanced electronics manufacturing.

Choose Waffle Slab Floor When:

- Project budget is a primary driver, and you aim to reduce material and installation costs.

- The facility requires good airflow and anti-static performance, but without complex or large-scale underfloor cabling.

- There is a preference for simpler, faster construction, and staff can manage the higher cleanliness standards during installation.

- Maintenance involves minimal floor lifting and underfloor inspections.

Additional Considerations

- Technical support: Raised access floors are typically supplied and installed by vendors with specialized expertise, while waffle slab installation places more emphasis on the skill of individual builders, especially during epoxy treatment and finishing.

- Expansion and flexibility: Future reconfiguration is often easier with raised access floors; however, if the cleanroom layout is unlikely to change, either system may provide reliable long-term use.

Our Recommendation:

Analyze your operational workflow, anticipated equipment, airflow requirements, maintenance approach, and budget. In settings where future modifications, cable management, or heavy-duty needs are expected, the raised access floor is typically preferred. For projects prioritizing cost savings and streamlined installation without extensive cabling or utility changes, the waffle slab floor is a practical alternative.

For cleanroom projects that demand outstanding load capacity, anti-static performance, ease of installation, and long-term durability, the HUIYA 1250LBS Aluminum Raised Floor for Clean Rooms is an excellent choice. Designed with advanced corrosion and moisture resistance, this raised floor system combines a robust cementitious core with an anti-static HPL surface, supporting both heavy equipment and high-volume cable management. The system meets international standards, offers precise leveling, and features non-combustible materials for enhanced safety, making it a dependable solution for a wide range of cleanroom and high-tech environments. For more details, visit the official product page.

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

Global Data Center Trends 2026

匯亜、新たに塩霧試験装置を導入 OAフロアの品質防線を強化

회아, 새 염무시험장비 도입해 이중바닥재 품질 방호선 단단히 만듦

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS