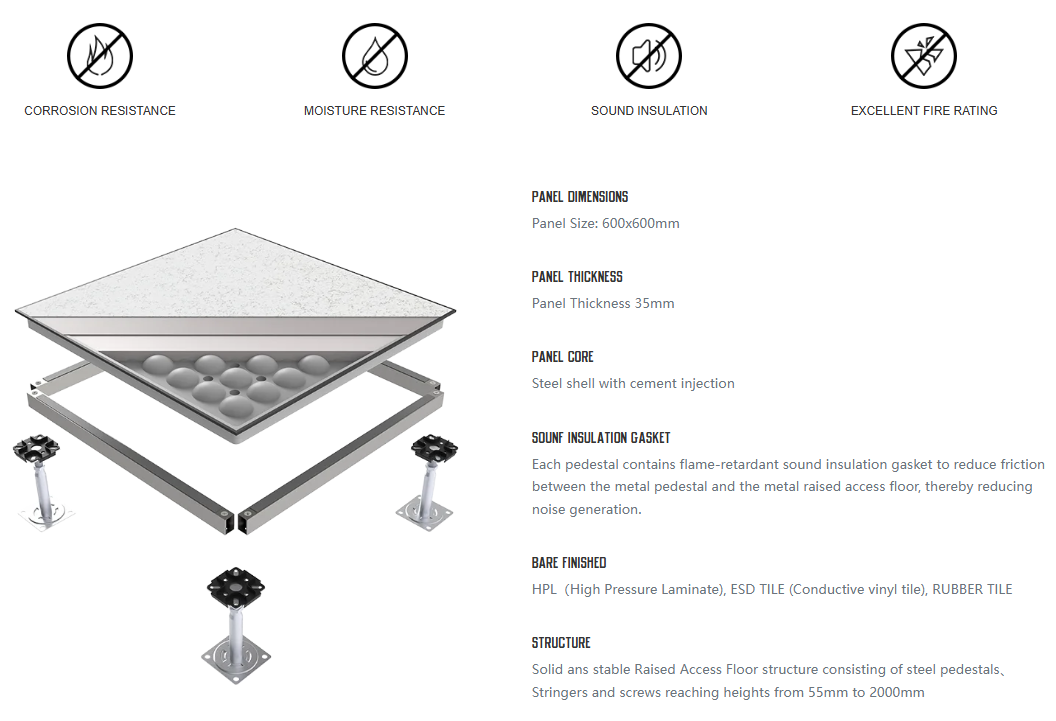

Anti-Shift, High Compatibility, Sound Insulation — Targeting Secondary Installation & Repair Pain Points

On March 2, 2025, Huiya Raised Access Floor joined the calcium sulfate electrostatic-discharge (ESD) floor installation at Nantong Construction’s site in Taicang’s Huangjing Town (Chaoya Taicang Data Center – Shanghai Park). During work, the team spotted a long-standing industry headache: Calcium sulfate ESD floors often shift, misalign, or form uneven joints during reinstallation—for this not only harms laying precision but also hikes labor and time costs.

1,Reinstallation Challenges Spur Tech Breakthrough

On-site feedback flagged a core need: Stabilize and precisely position floors to stop shifting. As a raised access floor specialist, Huiya thus quickly launched R&D for new brackets.

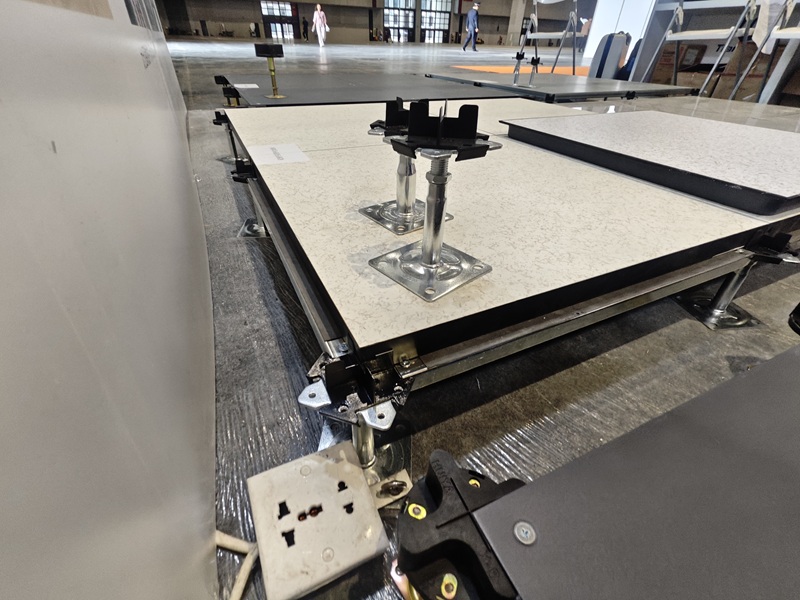

Image: Left — Huiya’s product display hall; Right — Close-up of the new anti-shift bracket.

2,Multiple Advantages Tackle Industry Pain Points

After technical breakthroughs, Huiya’s new anti-shift bracket for calcium sulfate ESD floors debuted. It not only solves shifting but also breaks new ground in compatibility and function:

①Precision Positioning Ends Reinstallation Misalignment

First, the bracket’s guide slot helps raised access floors align with clamps. Paired with a tapered positioning plate, it locks floors into preset spots during reinstallation, thereby avoiding shifts. The 2mm-thick card accounts for beam and pad thickness, ensuring a perfect floor fit and further boosting stability.

②Wide Compatibility Across Floor Types

Second, besides standard calcium sulfate ESD floors, the bracket fits six-sided steel-clad calcium sulfate raised access floors. Its design matches their curves, ensuring tight installation and thus breaking traditional brackets’ narrow compatibility.

③Upgraded Sound Insulation Cuts Metal Noise

Third, the bracket’s special structure isolates floor panels, avoiding metal collision noise. As a result, it enhances user experience in quiet-sensitive spaces like data centers and labs.

Images (left to right): Bracket installed on a floor; Two brackets up close; Bracket in a data center.

3, Overcoming Hurdles for Successful Deployment

However, R&D wasn’t smooth. During testing, the team faced issues like poor clamp-floor curve matching and low guide slot precision. By repeatedly adjusting mold parameters and optimizing clamp curves and slot angles, they finally achieved seamless fitting between brackets and raised access floors.

After rounds of testing, the new bracket completed mass production and hit the market. To further boost stability, Huiya tested it with Xiaowest KU928 floor bracket adhesive. The “mechanical fixing + adhesive reinforcement” double guard cuts loosening risks after reinstallation, thus offering a new solution for industry maintenance.

Today, this anti-shift, high-compatibility, and sound-insulating bracket serves in multiple data center projects. Its stable performance wins contractor and client acclaim, so it supports reliable secondary installation and long-term maintenance of calcium sulfate ESD floors.

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS