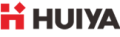

HUIYAINC Factory is A Business to Business(B2B) Type Raised FLoor Manufacturer In China. We Make Raised Floor Series includes:1:HUIYA GRC OMEGA Raised Floor(500x500x26mm) 2:HUIYA Steel Bare Raised Floor(600x600x33mm)With Corner lock Systems or Bolted Stringer Systems. 3:Calcium Sulphate Raised Floor(600x600x30mm) 4:Die Cast Aluminum Raised Floor Systems(600x600x55mm). 5:Anti-Static Raised Floor Systems (600x600x35mm). HUIYAINC Factory Provides various of Planings of Raised Floor Solutions About Raised FLoor and Understructure Customization.

Founded in 2005 in China, HUIYAINC is a company specialized in the field of The Raised Floor, False Floor, and Industrial flooring that represents the alliance of the best quality raised floor brands and a variety of systems. we are able to offer you technically sophisticated and high-quality double-floor systems. In addition, custom-made products and solutions are not a hurdle, but a challenge for our experienced team. HUIYA Technical Floor products offer important advantages for an ecological, modern, and responsible construction.

PERFORMANCE TO STANDARD GUILD PER CISCA

Recommended Test Procedures for Access Floors(2007)

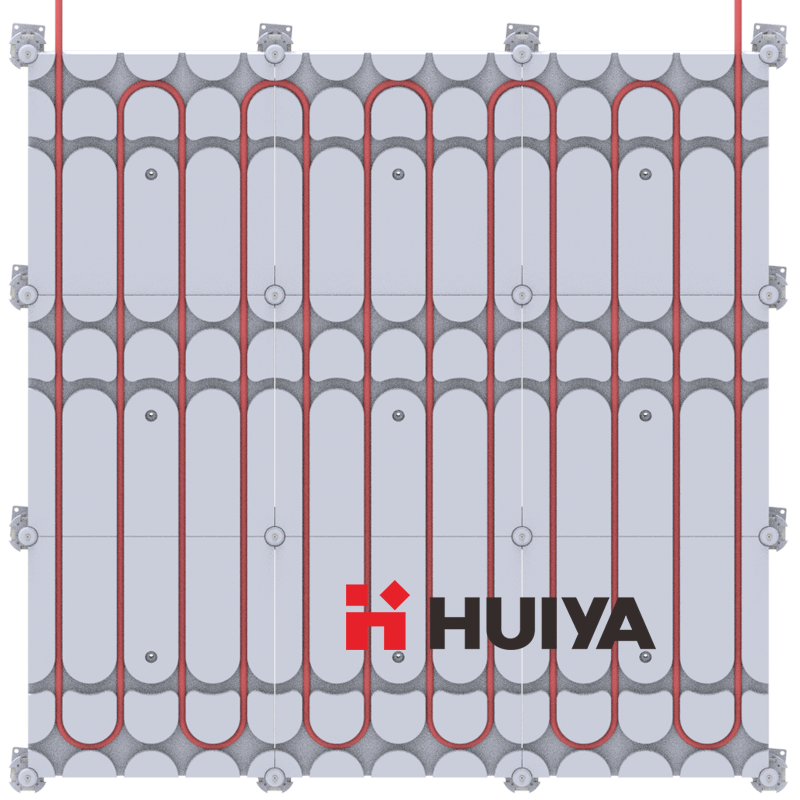

HUIYA Raised floor pedestal is made of Cold dipped Galvanised Steel Plate (Head Plate & Bottom ) and Solid M16 Rod. The Pedestal will be provides with an adjusting and locking nut to maintain the assembly at a selected height,which requires a deliberate action to change the height setting and which prevents vibration displacement.

HUIYA Raised Floor Stringer Size: 21x32x570mm and it is cold dip galvanized Steel to anticorrosion. HUIYA Raised FLoor Stringer is connection with Raised FLoor Pedestal.(We aslo called Stringer Bolted Raised Floor Structure).

How to install the Raised Floor?

1.First,on the ground where the raised floor is to be laid,release the ground grid lines of the raised floor according to the plank plan of the raised floor and the axis position of the site.

2.Install support feet at the cross position of the horizontal and vertical lines of the platoon,and smooth or fill the floor as much as possible to ensure the stability in the later period.

3.After installing the feet,perform basic treatment on the ground,and use a vacuum cleaner to remove the dust and debris left by the previous construction to ensure that the ground is clean.

4.Wipe the base of the support rod with adhesive,and install the floor support foot firmly on the subfloor with anchor bolts.And according to the actual height of the ground,adjust the height of the supporting feet,use the relevant tools to make partial bottom adjustments,after the adjustment,add a leveling nut and a leveling nut with anti-vibration displacement to the thread(or aluminum column).

5.Install the decorative panels of the raised floor.Before assembling,draw lines around to make the connection fit.If you need to cut the plate version,don’t do it in the room to avoid dust.

6.After laying the decorative panels,the installation of the entire raised floor is over.Use a vacuum cleaner to clean the house thoroughly